Welcome to Global Die & Extrusion Technology Inc.

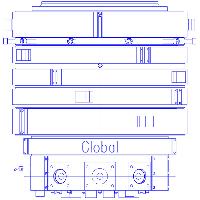

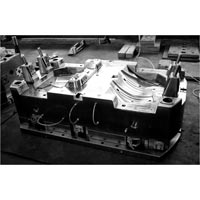

With over 24 years experience, we offer with confidence our knowledge and ability to manufacture new equipment as well as retrofit the existing equipment. Furthermore, you can count on the exceptional value of global technology to meet the precise demands of you and your clients today, tomorrow and for years to come. Our specialization includes the exclusive die and extrusion components design in addition to manufacturing of complete blown/cast film dies. our product line includes; extruders, manual & hydraulic screen changers, monolayer & co-extrusion dies, stationary, rotating or oscillating die blocks with die carts, adapters, single & dual lip air rings, die with auto gauge system, bubble cages, oscillating nip assemblies, variety of winders, automation and exclusive processing simulation software. This pro/process software gives a processor the capability to predict how their multilayer die will behave when processing a variety of resins through the system prior to producing any film. This allows the processor to simulate all film development trials/structures through the computer within minutes. Precise manufacturing tolerances, design accuracy and a superior final product are assured by direct data interface between the cnc machines and custom in house design software. However, global die & extrusion technology inc.’s dedication to high quality workmanship and service assure the best possible customer's solution. In addition to the above, global provides project consultancy & technology development with satisfaction. For example; complete solution for barrier blown, cast, double bubble, nylon casing, shrink, cling and coating film applications. No work is big or small. We fully appreciate and respect our customers' need for confidentiality expert in retrofit blown/cast film equipment with our extensive know-how awareness of blown/cast film extrusion equipment, we will be able to help our customer with customization of state of art components and modules from its current product range. Our retrofit program is mainly focus on improved film quality, film gauge tolerances significantly, increased output and efficiency by increasing up-time and flexibility. We can make an appropriate suggestion with retrofitting your existing equipment and also provide intelligent solutions with gravimetric feeding, air ring, auto gauge system, extruders, die, cages, haul-offs, winders, and automation. It is not always true that you need a new line to increase the performance capacity of your film production. Our experience has exposed that, depending on product specifications, incorporating our exclusive die technology and appropriate components along with our innovative pro/process simulation software has given the best return on investment (roi). along with intelligent solution, we will provide our friendly and quick service at very reasonable cost. Extrusion die technology global delivers exclusive die technology for mono or co-extrusion systems as a complete package or in components to customer's specifications in order to produce the best quality films. Each die and individual spiral mandrels are design with a great consideration of individual material viscosity. Both mono and co-extrusion die spirals are designed by proven custom in house developed computer simulation software using the rheology of the resins. Consequently providing optimum output with reasonable flow back pressure. To guarantee the best design for each individual application global works directly with the customer, analyze proposed resins, layer configurations and provides maximum versatility. The global co-extrusion die is the most advanced and versatile blown film co-extrusion dies in the market designed with optimized performance. Precise manufacturing tolerances, design accuracy and a superior final product are assured by direct data interface between the cnc machines and design software. Its performance is further enhanced by its lowest wetted surface area, resulting in very short residence time, low pressure drop, and no resin hang up for easy purging. Global dies are available from 1 to 9 layers to suit customer's requirements.

-

President

Surendra Sagar

-

Year of Establishment

2013

-

Primary Business

Manufacturer

-

Annual Turnover

USD 1 to 5 Million Approx.

-

Market Covered

Canada, USA, Europe, China, and Russia